- #HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS CRACKED#

- #HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS FREE#

- #HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS CRACK#

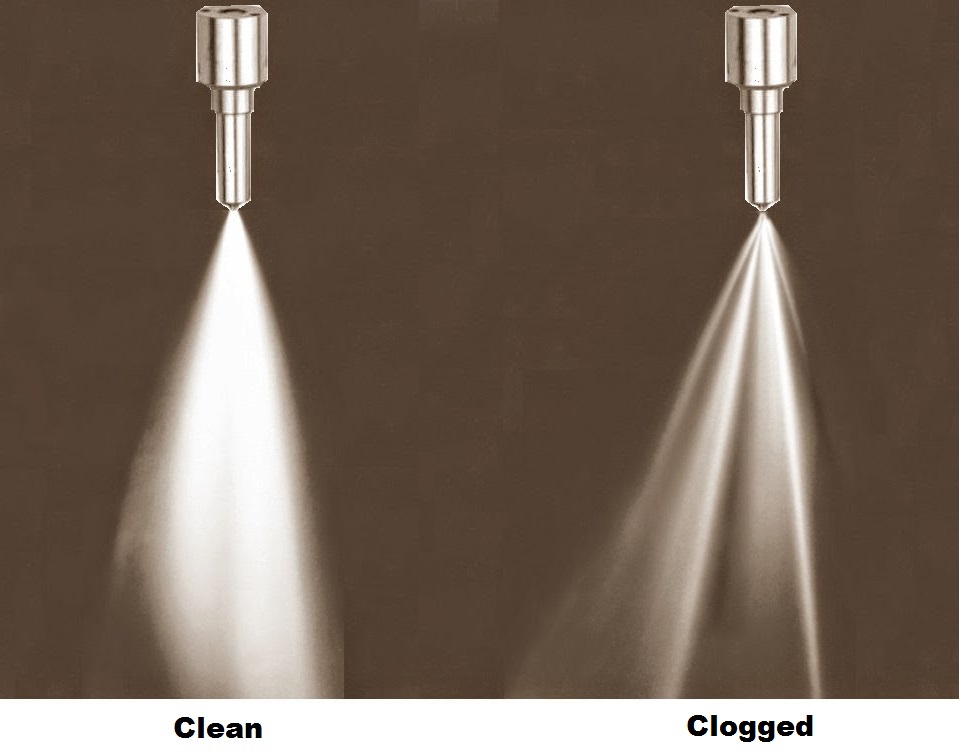

Next, crank the engine and see if the crank time is reduced. Do not use anything else or you may suffer injury or death from the high-pressure fuel.) This cap is made to withstand the high pressures associated with a common-rail system. (Warning: this “cap” is a special tool made by Cummins specifically for this test. Next, place the cap on the fuel rail where the fuel line was. The only way that you can isolate an individual cylinder is to cut off the supply of fuel - in order to do this in a common-rail system you’ll have to cap it off.įor the Cummins engine, start with the first cylinder and remove the hard line between the fuel rail and injector. What if you still can’t determine which one is causing problems? Then you’ll have to dig a little deeper and isolate each cylinder. This type of diagnosis can be very useful in trying to identify which injector may have an external crack.

#HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS CRACKED#

If the injector is cracked externally and producing a smoke wisp, you will be able to smell the hint of diesel fuel in the air. But this wisp should not be confused with blowby, which will be seen also. The wisp of smoke that can sometimes be seen is actually the atomization of fuel being released from the crack. Sometimes, if the injector body is cracked externally, you may be able to notice a small wisp of smoke from the injector. With a light, study the injector body of each cylinder. First remove the valve cover, then crank the engine and let it idle. So when an injector becomes cracked and the fuel has leaked down in the injection system, crank times will become almost tripled in order for the fuel system to re-prime and the desired threshold reached in order to fire the engine.ĭetermining exactly which injector is cracked can be a lengthy process.Ĭummins recommends a simple visual test to start. In a Cummins engine, the injectors are not actuated by the controller until the fuel rail pressure reaches the threshold. Normal common-rail systems will operate at 5,000 psi at idle and can reach up to 30,000 psi at wide open throttle (WOT). This is how long it will take the common-rail pump to build fuel pressure to the “threshold.” The threshold for cranking is when the fuel rail pressure reaches around 5,000 psi. When the leak down occurs, the engine has to spin over for an excessive period of time in order to re-prime the injection system.Ī normal crank time in a common-rail injection system is usually around three to five seconds.

#HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS CRACK#

When the engine is shut down, the crack in the injector’s body will often cause fuel to drain back from the fuel lines and rails back to the tank. In addition, the customer may notice some fuel dilution in the oil by seeing that the oil level is rising on the dipstick.

When the body is cracked, the engine will not necessarily produce a miss but will cause other problems, which can be even more difficult to pinpoint.Īlthough the injector body can be cracked, the engine may still run fine but just take an extended period of time to crank. One of the most common failures occurs when an injector body becomes cracked. However, injectors can fail in ways other than becoming just worn out or tired. In cases such as these, the scan tool generally will pinpoint the cylinder with the contribution problem. Like anything else, injectors can get tired and become weak over time.Įven though they are electronic, sometimes the mechanical components inside the injector may also become worn, cease to function properly and even fail. But some problems may be tougher than your customer - or you - think. The good thing about electronic diesels is that the technician can link up with a scan tool to analyze data in order to try to pinpoint problems. Owners often think that because diesel engines are now computer-controlled, the technician should be able to hook up a scan tool and immediately see what is going on.

#HOW TO DIAGNOSE FUEL INJECTOR PROBLEMS FREE#

FREE Diesel Diagnosis and Repair Articles & Videos (click here)Ī phrase that customers often use is, “This is a diesel engine the problem should be easy to diagnose.” The most accurate part of that statement is that it is a diesel engine.Ĭertainly, there are some common repairs needed on specific engines that are easy to do, but that doesn’t mean everything else will be easy to diagnose.

0 kommentar(er)

0 kommentar(er)